Coping with heat in construction: Sealing and bonding

Having the ideal climatic conditions for construction is a topic that is often discussed in relation to cold, wet weather, when the elements are less than idyllic for building works. But across Europe, we also have to consider how hot, humid weather can affect a construction project and it’s imperative that the products and solutions used are made to withstand such conditions.

With our product brands offering solutions that cover all six sides of the building, we’ve collated our top tips for finding the correct solutions to use in warmer climates. In part 1 of these series of posts, discover the types of sealing, cladding and bonding solutions that are available to withstand applications during the warmer months.

Sealing and bonding solutions

Exterior work can be subjected to a wide range of conditions; therefore, sealing and bonding solutions require a high level of durability to withstand the elements. As with many sealing, bonding and insulation materials, installations – and specifically curing times – can be affected by temperature and this should be a key consideration when choosing products.

Applying PU Foams

Take PU Foams for example, the best temperature to apply a PU foam is between +5°C and +35°C. This is a fairly wide temperature range, but at higher temperatures the substrate is often drier. PU foams need moisture to harden and so, in hot and dry climates, you will need to moisten the surface to get the best result. A plant sprayer or similar tool can be very useful in these circumstances!

During breaks or down time always make sure that the polyurethane foam cans do not get too hot. Leaving canisters in a hot work van or in full sunlight is not a good idea as the heat will increase the pressure in the can which could, in a worst case scenario, cause the can to overheat and explode.

Would you like to know more about processing PU foam and frequently asked questions?

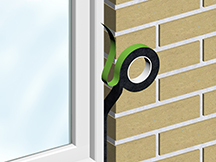

Warmer temperatures unravelling foam tapes

It is not just pressurised cans that can be affected by warmer weather, however. Foam tapes, such as those used for window sealing are made specifically to expand once unrolled in order to fill and seal gaps. Hot weather can result in the tapes expanding at a faster rate, meaning that installations may need to be carried out much more quickly to ensure a perfect finish. We recommend storing tapes in a cool, dry place at a temperature between +1°C and +20°C – using a cool box or fridge can be very handy for this.

Keeping coatings cool

Liquid products such as sealants or coatings will not only become more liquid due to the heat, but they will also dry faster. Although this will speed up curing times, which may be a benefit for some projects, it does also mean that the products may cure on processing tools such as scrapers or brushes. Keeping a cool box to hand can also be very beneficial for such products.

Keep your eyes peeled for the next post in this series which considers failproof flooring solutions for areas exposed to extreme heat.