Coping with heat in construction: Turing up the heat on fire protection

So far in this series of blog posts, we’ve shared top tips for using sealing and bonding solutions in warmer weather, and the best flooring solutions to choose for areas exposed to extreme heat. But what about products that are developed specifically to keep a building safe in the event of arguably the most dangerous source of extreme heat – fires? Here, we explore protective solutions that can help to keep your building, and those who use it, as safe as possible.

First class fire protection for constructions

Protecting a building from fire is not limited to a building’s content. The construction itself must be protected to give inhabitants the best chance of evacuating before the fire warps the structure. There are several products that can be used to provide fire stopping and safety, such as intumescent coatings, fire barriers for compartment walls and fire insulation wraps, but which is right for your building? Let’s take a look at the differences in solutions and applications.

Intumescent coatings for steel protection

Protecting steel from reaching structural failure temperatures, intumescent steel coatings can give structural stability for up to 120 minutes, providing valuable time for users in the building to evacuate, and emergency services to reach the building.

Protecting steel from reaching structural failure temperatures, intumescent steel coatings can give structural stability for up to 120 minutes, providing valuable time for users in the building to evacuate, and emergency services to reach the building.

Intumescent coatings that have been engineered to be compatible with primers and topcoats are ideal for structures that require a fine finish.

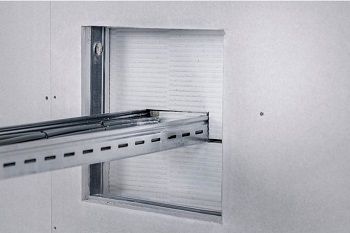

Fire barriers

Fire barriers can be used to stop a fire from rising from level to level in a building’s façade. Often, these are either open state barriers or closing fire barriers. Ventilated fire barriers react in case of a fire and expand to close the gap in a façade whereas closing fire barriers, such as curtain walls are built to close the gap between the façade wall and the floor slab.

Fire insulation wraps

A further offering of fire stopping products includes insulation wraps – these can be mineral wool foil faced wraps used for insulation around metal pipes, cables or other services. These are used to prevent damage to pipework or cables in the event of a fire.

Find out more about fire stopping and intumescent coatings available and how they can protect your building

Just because some products are made to withstand intense heat, sometimes for up to 120+ minutes, the initial application of the products can still be affected by temperatures. Acrylic based products for example, such as coatings, are easier to apply when it is warmer, say in +5°C to +40°C.

As with any product in a pressurised container, be careful not to sit foam canisters directly in sunlight, as there is a risk of explosions.

Whereas fire protection can be added at various stages of construction, our next post considers the building materials themselves, and how they can be chosen at the planning stage to keep the heat in during the winter months and keep the heat out during summer.