Behind the Build: How Tremco CPG’s Line Walks Help Offsite Customers Improve Efficiency

Behind the Build: How Tremco CPG’s Line Walks Help Offsite Customers Improve Efficiency

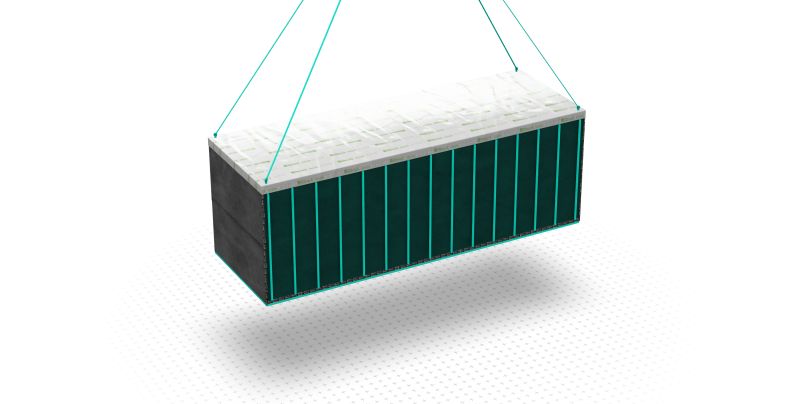

At Tremco CPG Offsite, our commitment goes far beyond supplying products — we partner with our customers to improve build quality, reduce waste, and streamline operations. A key part of how we do that is through our customer-focused line walk process: a hands-on, on-site review designed to understand exactly how our products are used in real-world offsite manufacturing environments.

By walking the line with our customers, we gain invaluable insights into their build process, priorities, and pain points. It’s not about turning up with a fixed solution — it’s about listening first, asking the right questions, and working together to identify smarter, safer, and more cost-effective ways of doing things.

We often start with a simple goal: understand what the customer wants to achieve. From there, we observe how products are being applied on the line, how materials flow through the space, and how different teams interact with our solutions. We talk to the operators using our systems daily, not to instruct them, but to learn from them.

Our business development Adam Guest emphasises: "We don't just talk to people, we listen, we take time time to talk to people and really listen and understand their points. That’s how we get the key information — why a certain product is being used, where the delays are, or how a material could be made easier to handle or cure faster.”

During a recent visit, for instance, our team noticed the use of silicone behind floorboards. By engaging with site teams, we were able to suggest an alternative foam product that not only matched performance but significantly reduced overall material cost. That insight came directly from understanding the build sequence and knowing which performance characteristics were truly essential.

These line walks also help customers with prioritisation. Rather than trying to overhaul an entire process at once, we work together to identify a shortlist of improvement opportunities — whether it's switching out a product, adjusting application techniques, or rethinking sequencing. From there, we trial changes one at a time, evaluating performance, cost, and practical impact along the way.

In some cases, our conversations lead to important health and safety gains. One project raised concerns about adhesive fumes in enclosed areas. By highlighting the risks associated with certain chemicals, such as cyanoacrylates, we helped the customer explore safer alternatives and implement better ventilation practices.

Each line walk gives us — and our customers — a portfolio of ideas. Some are quick wins; others take time to develop. But the process always starts with collaboration and a shared goal: improving outcomes.

Ultimately, Tremco CPG’s offsite line walks aren’t about selling more products — they’re about delivering more value. By embedding ourselves in the customer environment and really understanding the details, we help offsite manufacturers work smarter, safer, and more efficiently.